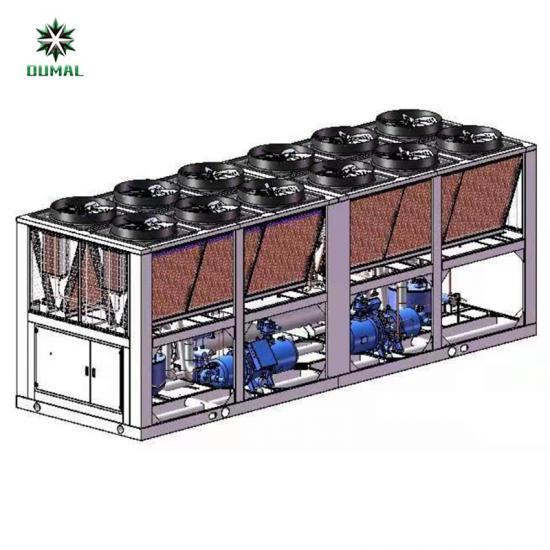

100tr Air Cooled Chiller For Plastic Process Cooling Water System

A 100-ton air-cooled screw chiller is a cooling system that uses a screw compressor and air cooling method to provide 100 tons (or 100 refrigeration tons) of cooling capacity. It is commonly used in industrial applications where large cooling loads are required, such as in commercial buildings, manufacturing facilities, data centers, and process cooling applications.

The main features of a 100-ton air-cooled screw chiller include:

Cooling capacity: The chiller is designed to provide a cooling capacity of 100 tons, which is equivalent to 1,200,000 BTU/h or 351.6 kW of cooling power.

Screw compressor: The chiller is equipped with a screw compressor, which is known for its high efficiency, reliability, and smooth operation. The screw compressor is designed to handle large cooling loads and maintain consistent cooling performance.

Air-cooled condenser: Unlike water-cooled chillers that rely on water for heat dissipation, air-cooled chillers use ambient air for cooling the refrigerant. The chiller is equipped with an air-cooled condenser that transfers heat from the refrigerant to the surrounding air.

Efficient heat exchanger: The chiller incorporates a high-efficiency heat exchanger that maximizes heat transfer between the refrigerant and the cooling medium (air or water). This helps to optimize the cooling process and improve energy efficiency.

Integrated controls: The chiller is typically equipped with advanced control systems that allow for precise temperature and pressure regulation, as well as protection mechanisms to ensure safe and reliable operation.

Compact design: Air-cooled chillers are often designed to be compact and space-saving, making them suitable for installations where space is limited.

Easy installation and maintenance: The chiller is designed for ease of installation and maintenance. It may come with features such as removable panels, accessible components, and user-friendly interfaces to simplify operation and service.

Overall, a 100-ton air-cooled screw chiller provides efficient and reliable cooling for medium to large-scale applications, offering a balance between performance, cost-effectiveness, and ease of installation and maintenance.

Our 100TR air cooled chiller is specifically designed to meet the cooling demands of the plastic processing industry. 100 ton air cooled screw water chiller offers efficient and reliable cooling solutions that ensure process stability and enhance product quality. Featuring advanced refrigeration technology and durable construction, this 100 ton air cooled screw water chiller is ideal for a wide range of plastic processing applications.

100 Ton Air Cooled Screw Water Chiller Key Features:

High Efficiency Cooling:

- Equipped with high-performance compressors to ensure efficient and stable cooling.

- High-efficiency evaporator and condenser design for improved heat exchange performance.

Intelligent Control:

- Advanced PLC control system for real-time monitoring and adjustment of operating parameters, ensuring optimal performance.

- User-friendly touch screen interface for easy operation and maintenance.

Energy Saving and Environmentally Friendly:

- Air-cooled design eliminates the need for an external cooling water source, reducing water consumption.

- Utilizes eco-friendly refrigerants that comply with international environmental standards.

Safety and Reliability:

- Multiple safety protection features including overload protection, low-pressure protection, and high-temperature protection to ensure safe and reliable operation.

- Constructed with high-quality materials and components for long service life and excellent corrosion resistance.

Easy Maintenance:

- Modular design allows for easy disassembly and cleaning, making maintenance simple and quick.

- Comprehensive after-sales service and technical support to ensure customer satisfaction.

Details of the 100 Ton Air Cooled Screw Water Chiller

Details of the 110 Ton Air Cooled Screw Chiller.

Testing Video of 400 kw Air Cooled Screw Chiller

Application range of air-cooled screw chiller:

Plastic industry: accurately control the mold temperature of various plastics processing, shorten the plastic molding cycle, and ensure the stability of product quality.

Electronics industry: Stabilize the molecular structure of electronic components on the production line, improve the qualification rate of electronic components,

Electroplating industry: control the electroplating temperature, increase the density and smoothness of the plated parts, shorten the electroplating cycle, and improve the production efficiency

Construction industry: supply chilled water for concrete to make the molecular structure of concrete suitable for the requirements of construction purposes, effective Enhance the hardness and toughness of concrete.

Vacuum coating: control the temperature of the vacuum coating machine to ensure the high quality of the coated parts.

Food industry: used for high-speed cooling after food processing to adapt to packaging requirements. There is also controlled fermentation, The temperature of the food, etc.

Chemical fiber industry: freeze-dry air to ensure product quality.

Dairy products, beverages; the production process often requires rapid cooling after heating, The steel pipe, water tank, and water pump of the chiller are required to be made of stainless steel to meet sanitary requirements.

Medicines, biological products; low temperature and low humidity environment is required during production and storage.

The line needs to be heated to reach a certain temperature before starting, and it needs to be cooled by chilled water due to its own heat generation after starting

To keep the temperature low.

Tempered glass; the general glass is heated at high temperature and then quickly cooled, the cooling water temperature should not be too high, otherwise

Will affect the quality of tempering. The industrial chiller is used to provide frozen water for cooling, and the water temperature does not love the influence of the ambient temperature.

Ensure the quality of the product.

Aquaculture; hotels, seafood restaurants, seafood farms, aquariums, providing frozen water in summer and heat in winter.

100 Ton Air Cooled Screw Water Chiller Product Specification (based on 15 degree)

| Item Model | OMC-120ADH | ||

| Cooling Capacity | kcal/h | 302376 | |

| KW | 351.6 | ||

| Ton | 100.0 | ||

| Btu/h | 1200000 | ||

| Input Power | KW | 112.6 | |

| Max.running current | A | 264 | |

| Power | 3PH-380V/415V 50Hz (3PH-220V/440V 60Hz ) | ||

| Refrigerant | Type | R22 ( R407C ) | |

| Charge quantity | kg | 84 | |

| Control Mode | Expansion Valve | ||

| Compressor | Type | Semi-Hermetic Screw | |

| Power | KW | 51.9 x 2 | |

| Start-up Mode | Y-△ | ||

| Capacity control | % |

0-25-50-75-100 (0-33-66-100) |

|

| Evaporator | Type | Shell and Tube | |

| Chilled water flow | m3/h | 60.5 | |

| Pipe Diameter | lnch | 3" | |

| Condenser | Type | Air cooled high-efficient inner threaded copper-tubing aluminum fin type | |

| Fan | Type | Low noise outer rotor | |

| Power | KW | 8.8 | |

| cooling air flow | m3/h | 120000 | |

| Dimension | Length | mm | 4800 |

| Width | mm | 1950 | |

| Height | mm | 2200 | |

| Net Weight | kg | 3250 | |

| Running Weight | kg | 3460 | |

| safety protection: compressor over heat protection, over load protection,high and low pressure protection,reversed and lacking phase protection, anti-freezing protection, flow switch | |||

en

en es

es