Hot selling 15rt /20 HP 50kw air cooled chiller for plastic cooling

The 20HP air-cooled water chiller, usually scroll compressors, is widely used in plastic processing cooling systems. These chillers, also called extrusion chillers, are perfect for cooling plastic extrusion molding lines, offering both air-cooled and water-cooled options.

The application of chillers in the plastics industry is mainly reflected in the following aspects:

Cooling molds: During the plastic molding process, the mold needs to be cooled quickly after injection to shorten the molding cycle. The low-temperature cooling water provided by the chiller can accelerate the cooling of the mold, thereby speeding up production.

Control temperature: By accurately controlling the temperature of the mold, the chiller helps to maintain the consistency and dimensional stability of plastic parts and reduce quality problems caused by temperature fluctuations. 1.

Improve product quality: Proper cooling can reduce surface marks and internal stress of plastic products, prevent products from shrinking and deforming, and improve the overall quality of products.

Energy saving: An efficient cooling system can reduce unnecessary energy consumption while reducing production costs. By optimizing the cooling cycle, the chiller helps to improve overall energy efficiency.

When selecting and using a chiller, you need to pay attention to the following points:

Cooling capacity and temperature control accuracy: Select a chiller with appropriate cooling capacity according to actual production needs, and ensure temperature control accuracy to ensure consistency of product quality. 3.

Reliability and durability: The plastic packaging industry is usually produced continuously, requiring the chiller to have high reliability and durability. Choose a chiller manufacturer with reliable quality and good brand reputation to ensure that the equipment is stable and reliable during long-term operation.

Environmental protection and energy saving: With the improvement of environmental awareness, it has become a trend to choose environmentally friendly and energy-saving chillers. This type of chiller uses advanced energy-saving technology to reduce energy consumption and reduce the impact on the environment.

By reasonably selecting and using chillers, the plastic industry can improve production efficiency, ensure product quality, and achieve sustainable development.

Air-Cooled Industrial Chiller Products Information

●:Air Chiller cooling capacity 1 Ton to 40 Ton

●:Temperature control 5℃ to 35℃

●:Temperature stability ±0.5℃ to ±2℃

●:Large Copper Condensing Coil with Aluminum Fins

●:Built-in SS water tank and water pump

●:Shell & tube or SS Plate Heat Exchanger for optional

●:Schneider Electrical components & Mic-computer control panel

●:Air cooled chiller is Easy installation and energy saving

●:All models and cooling capacity are available

More Pictures of Air Cooled Chiller

Application of Air-Cooled water Chiller

As Air Cooled Type Chiller No Need to Use Cooling Tower, It's easy installation and moving, Scroll type chiller air cooled industrial chiller is widely used in plastic industry: such as injection molding machines, extruding machines, Stretch film machines, bottle blowing machines; electroplate industry, Medical chillers, laboratory chillers, Electronics industry, textile industry.....

20 Ton Air chiller Products Specification

|

Model Item |

OMC-20A |

||

|

Cooling Capacity |

KW |

54 |

|

|

Kcal/h |

46440 |

||

|

Ton |

15.4 |

||

|

Btu/h |

184300 |

||

|

Input Power |

KW |

18 |

|

|

Power supply |

3PH-380V 50Hz / 440V 60Hz |

||

|

Temperature Range |

℃ |

5-35 |

|

|

Refrigerant |

Type |

|

R22(R407C/R410A/R134A) |

|

Compressor |

Control Mode |

|

Expansion Valve |

|

Type |

|

Piston Type / Scroll Type |

|

|

Power |

KW |

15 |

|

|

Chilled water |

Tank Volume |

L |

200/400 |

|

Tank Material |

|

SUS304 Stainless Steel |

|

|

Pipe Diameter |

Inch |

2〃 |

|

|

Pump |

Lift |

m |

20 |

|

Power |

kw |

2.2 |

|

|

Evaporator |

Type |

|

Tank with coil(Shell and Tube) |

|

Chilled Water Flow |

m³/h |

9.3 |

|

|

Condenser |

Type |

|

High efficiency copper condensing coil with Aluminum+Spiral axial flow fan |

|

Cooling Water Flow |

m³/h |

20000 |

|

|

Dimension |

Length |

mm |

2100 |

|

Width |

mm |

850 |

|

|

Height |

mm |

1600 |

|

|

Weight |

KG |

850 |

|

|

Safety Protection: Compressor overheating protection, over-current protection, high and low pressure protection, over-temperature protection, flow protection, reversed and lacking phase protection, exhaust overheating protection. |

|||

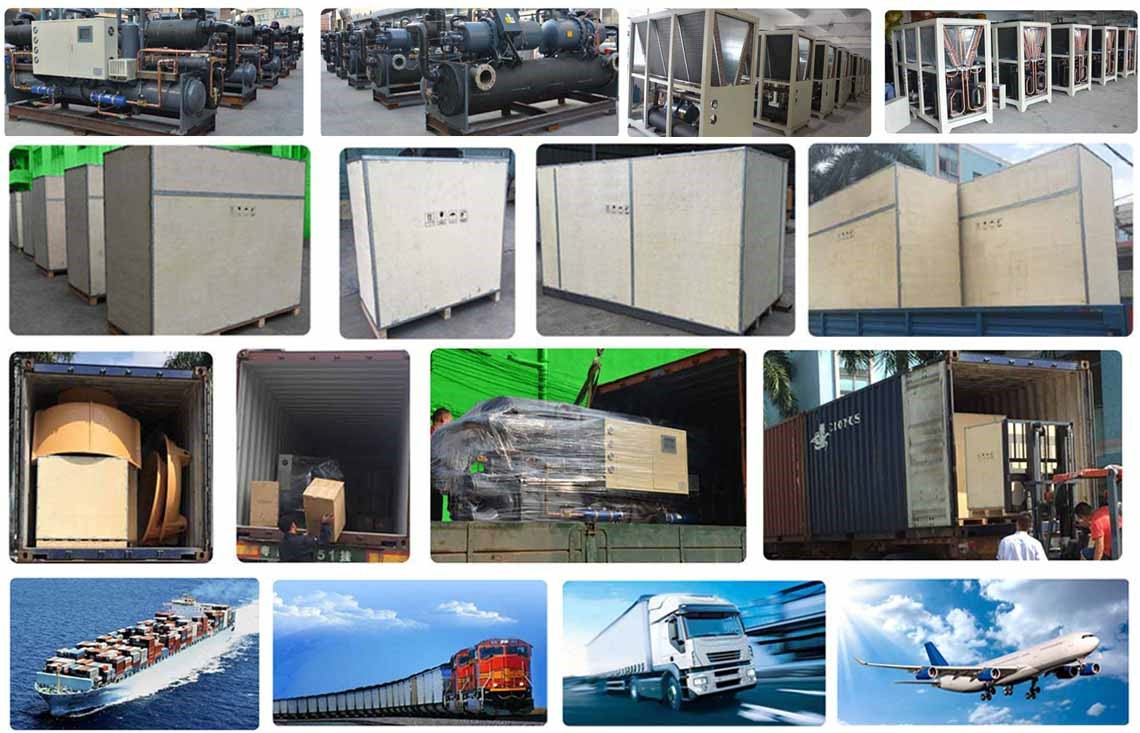

Scroll Type chiller Packing & Shipping

FAQ

Q1:Could you help us to recommend the model for our project?

A1: Yes, we have engineer to check the details and make the scheme for you. Based on the following:

1)Cooling capacity;

2)chilled water inlet and outlet temperature

3)chilled water flow

4) Refrigerant;

5) Ambient temperature;

6)Voltage;

7) Be used for what industry?

8)Any other special requirements?

Q2:How to ensure your product with good quality?

A2: All our products with CE certificate. And use the well-know brand accessories, such as copeland, danfoss,Hanbell, Bitzer compressor Emerson expansion Valve, Siemens controller.

also can be customized. All OUMAL Chillers are factory tested under load conditions to ensure good quality and easy installation for users

Q3:What's the warranty?

A3: 15 months warranty for free if confirmed by both side damage in the quality reason.

Q4:What’s your payment term?

A4: We accept T/T, LC, Western Union, etc. Normally, 30% deposit for production, 70% balance before shipment.

Q5:Are you a manufacturer?

A5: Yes, we have more than 15 years in water chiller business. Also have patent on the water chiller appearance .

The control box design make the unit safety and stably.

Q6:How can i Place an order ?

A: Click Below to fill the table or Call 0086 15112554736

en

en es

es